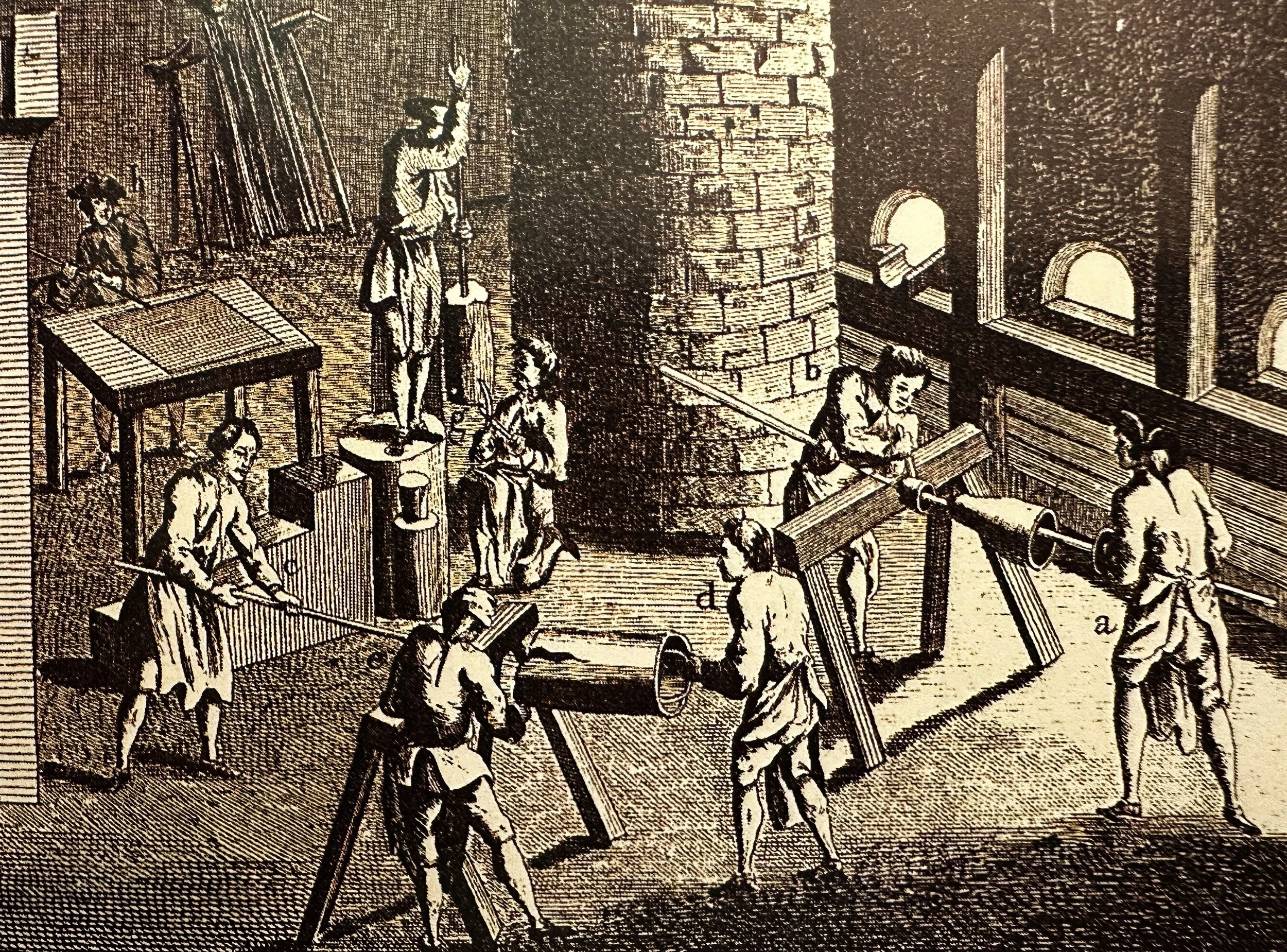

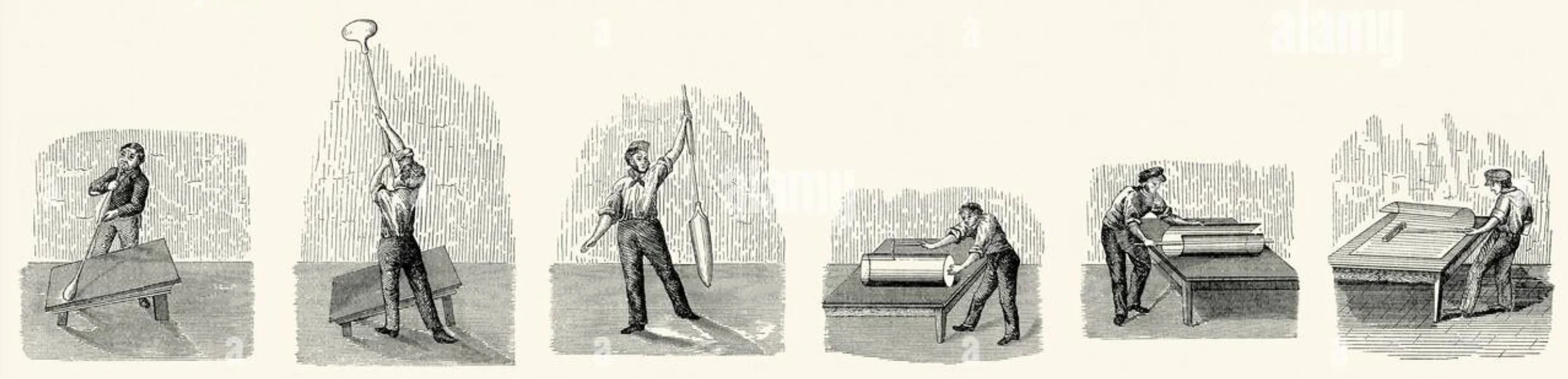

The traditional way to make coloured glass for stained glass artists to use is by blowing it, first into a bubble which is elongated by swinging it, then cutting the ends off to make a cylinder which is cut down the middle and then flattened into a sheet. These stages are shown in illustrations from different eras of glassmaking above and below.

When I started making stained glass windows you could buy sheets of glass known as ‘antique glass’ (because it was made by the antique mouth blowing method) made in Sunderland by Hartley Wood and Company. However Hartley Woods closed in 1997 and we started buying glass that was made in mainly Germany, France, America or Poland. When the company English Antique Glass stopped blowing sheet glass in 2022 ‘mouth blown sheet glass making’ was declared to be extinct in the UK by the Heritage Crafts Red List, where stained glass is listed as a still viable craft.

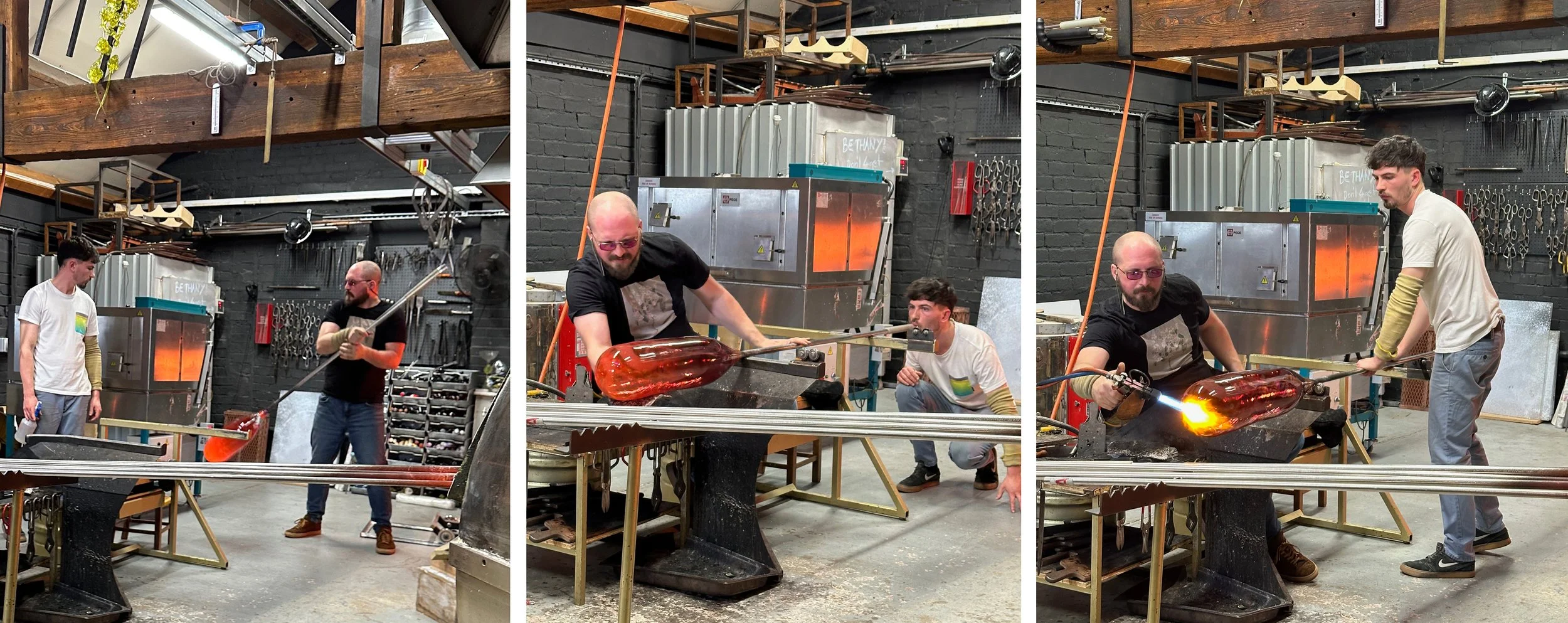

Eliot Walker and assistant Ryan working in the hot glass workshop at Blowfish Glass, Stourbridge.

On a mission to change this situation, the glassblower Eliot Walker (with Blowfish Glass) has started blowing sheet for stained glass on the site of the Red House Glass Cone in Stourbridge’s historic glass quarter. He learnt the tricks of the trade at Fremont Glass in Seattle, using a method suitable for small scale production. I took these photos (above and below) on a recent visitors’ day demonstration, a mesmerising watch that I would recommend to anyone.

The stages of turning a glass bubble into a cylinder.

The most fascinating part is not the blowing but the turning of the cylinder into the sheet - a process I will never describe in that airy way again when people ask me how the coloured glass I use is made. The cylinder was cold when it was cut (above right), Eliot then had to carry it with his tongs to the hot kiln, where the glass leaped around in a strange spiral before settling down (below left) and then being smoothed (bashed down rather) with a damp stick. The glass sheets that are made by this process are smooth and even, around 3mm thick, but contain beautiful colours and markings (below).

Left: The cylinder is flattened in the kiln. Right: six blown glass sheets on the Blowfish Gallery wall.

A box of offcuts: Left, as blown. Right, after flattening in my kiln (& with other coloured glass scraps added).

I’ve been adding antique glass into my smaller scale work recently, and have been running out of the streakies in my glass scrap boxes. So I bought a box of offcuts at Blowfish Glass that were the pieces from the slot that was cut down the middle or from the neck or base of the cylinder. The glass is easy to cut and mostly flashed (meaning the colours are in layers that can be removed) so will be ideal for sandblasting and maybe painting.

Two new pieces: Piece One, Piece Two

Before putting them away I couldn’t resist trying out a few pieces in combination with other glasses. I made four small pieces with an offcut in each one as follows:

Piece One: When I put the orange/green streaky next to a plain pale purple the combination was electric. Grey round the edge for a calming border.

Piece Two: The most lovely piece of cylinder neck glass - how would the streaky colours look next to black or white glass in comparison to the grey that I often use?

Piece Three: A panel that needed a border, miraculous colours that enhance the original piece.

Piece Four: This one was made to look like a window. The chunky glass from the cylinder bottom becomes a piece of sky or landscape next to the detailed painting that I did for an example panel.

Two old pieces with new glass added: Piece Three, Piece Four